Highlights from the Research Center

Structural materials

Development of Structural Materials with Concurrent Enhancement of Strength and Ductility: A Challenge in ESISM

Structural materials

Development of Structural Materials with Concurrent Enhancement of Strength and Ductility: A Challenge in ESISM

- Pursuing concurrent enhancement of strength and ductility in structural materials

- Improving mechanical properties without the use of critical elements

- Pioneering new theories on plastic deformation

Go beyond the simple dislocation theory

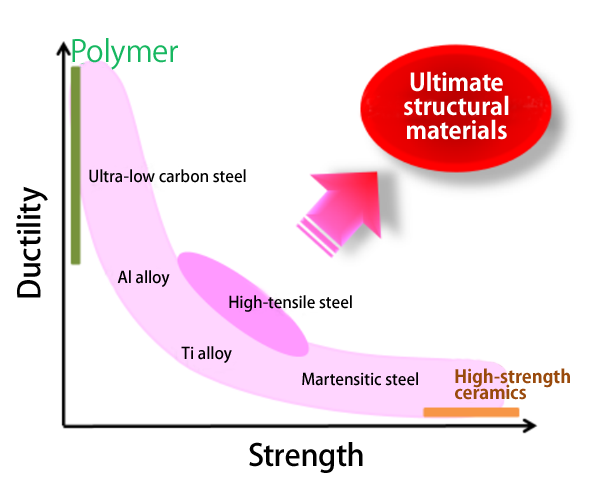

A large force applied to a metallic material will lead to plastic deformation, whereby the deformed material will not return to its original shape when the force is removed. Plastic deformation in metallic materials commonly arises through the activity of crystalline defects called dislocations. Encouraging the multiplication of dislocations and their movement facilitates plastic deformation, which manifests as ductility. Conversely, suppressing dislocation mobility increases the strength of the material, making plastic deformation more difficult. Therefore, the strength and ductility show a tradeoff relationship.

Most of the research to date on structural metallic materials has involved adding various alloying elements to strike a balance between strength and ductility. We are working to dispel this rigid idea of a predestined mechanism by creating innovative structural materials through microstructural control rather than the addition of alloying elements, and are working to construct a theory that supports this idea.

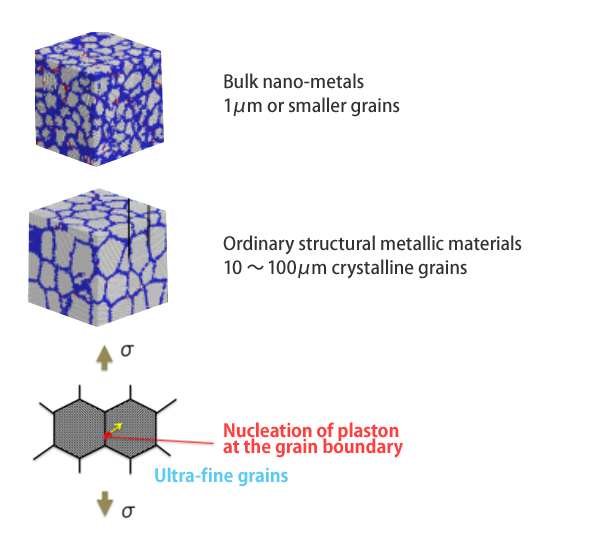

A unique phenomenon in bulk nanostructured titanium

Our research to date has primarily focused on materials called bulk nanostructured metals. Whereas ordinary metallic materials are polycrystalline having a grain size of 10 to 100 µm or more, bulk nanostructured metals are composed of submicron grains and are replete with grain boundaries. Generally, bulk nanostructured metals exhibit greater strength than polycrystalline materials having coarser grains. Through proper control of microstructure, even pure aluminum can be made as strong as iron, for example. Still, if one cannot escape the curse of the dislocation theory, reducing grain size may enhance strength, but ductility will be lost.

Nevertheless, we have found cases in which this dilemma can be overcome. In certain types of bulk nanostructured metals there occurs plastic deformation that defies the conventional mechanism of dislocations. In such cases, unique deformation mechanism different from primary dislocation glide was found to take place. They appear as secondary dislocation glide, deformation twinning, disclination motion and Martensitic transformation. Collective atomic motion at the grain boundaries acts as the nucleation for such plastic deformation. We call the collective atomic motion “plaston.” By proper control of the plaston, concurrent enhancement of strength and ductility is expected to be achieved.

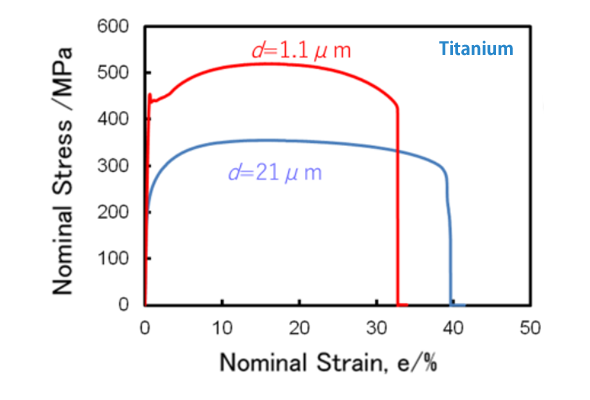

We found that the strength of the commercial grade unalloyed titanium with 1-µm grain size was nearly twice than that of the sample with 21-µm grain size. The ductility was not significantly lower in the 1-µm sample. There is simply no way to explain this phenomenon using conventional dislocation theory.

Utilizing advanced experiments and theoretical calculations to expand research

We studied bulk nanostructured titanium at the atomic level to find out what events are occurring internally. In a metal like titanium having an hcp crystal structure, dislocations are classified according to crystallographic orientation. When observing bulk nanostructured titanium with an electron microscope following compressive deformation, there was clear activity of numerous unique dislocations not seen in the deformation of ordinary titanium. These dislocations are responsible for the enhanced ductility in bulk nanostructured titanium. Similar research was conducted on magnesium having the same hcp structure as titanium in which we succeeded to balance strength and ductility by controlling grain size.

We performed various other experiments for analysis and evaluation, but an experiment using neutron diffraction at J-PARC yielded particularly important data. Since neutrons make it possible to see into the interior of a large sample as it deforms, we obtained important information on the phase transition and twinning occurring during the thermo-mechanical process.

Many significant results were also obtained through theoretical calculations, including an analysis of the collective atomic motion accompanying plastic deformation from the perspective of lattice vibrations (phonon) through first-principles calculations, and an analysis of the elementary processes in plaston formation through large-scale molecular dynamics simulations.

Figure 1 Defying the predestination of the dislocation mechanism

Figure 2 Nucleation of plaston at the grain boundary of bulk nano-metal

Figure 3 Achieving both strength and ductility in bulk nanostructured titanium

Isao Tanaka

Director, ESISM

Department of Materials Science and Engineering, Kyoto University

Collaborating institutes:

The University of Tokyo, Osaka University, the National Institute for Materials Science, Kyushu University, the Innovative Structural Materials Association (METI), and the Strategic Innovation Promotion Program (the Cabinet Office)

References:

- [1] Y. Z. Tian, et al; Sci. Rep., 5, 16707 (2015)

- [2]J.Y. Zhang, K. Kishida and H. Inui; Int. J. Plasticity 92 45 (2017)

- [3] A. Togo, and I. Tanaka; Scr. Mater., 108, 1 (2015)【Number of citations 535】