Magnetic materials

Characterization of Rare-Earth Permanent Magnets Using Quantum Beams

Magnetic materials

Characterization of Rare-Earth Permanent Magnets Using Quantum Beams

- Observation

- Computation

-

-

- Visualization of magnetic structures and magnetic interaction energy using quantum beams

- Coercivity analysis of neodymium magnets by high-resolution magnetic imaging using an X-ray microscope

- Elucidation of rare-earth site selectivity of Dy-substituted neodymium magnets by neutron diffraction

New evaluation/analysis techniques for developing high-performance magnetic materials

Critical elements, such as rare-earth metals, are used in the permanent magnet materials of motors that are incorporated in electric vehicles and power generators. Our research involves microstructural control aimed at developing magnetic materials with better performance while minimizing the use of critical elements. For this reason, new techniques with higher performance are needed for the internal characterization and analysis of magnetic materials.

Properties of magnetic materials include those originating at the atomic level (saturation magnetization, magnetic anisotropy constant, and Curie temperature) and properties originating in larger structures such as grain boundary phases and magnetic domains (coercivity and remanence magnetization). Neutron diffraction and X-ray diffraction are effective for analyzing magnetic and crystal structures at the atomic level, while small-angle neutron scattering and X-ray microscopy are effective for analyzing magnetic domain structures, and microtextures.

New methods of characterization/analysis using X-rays

We developed an apparatus for observing thinly sliced samples with an X-ray microscope that is capable of performing magnetic spectromicroscopy in local areas at the high spatial resolution of 15 nm. Even without the use of single crystals, basic properties in portions of polycrystalline materials can be analyzed from X-ray magnetic circular dichroism (XMCD) for use in the development of new materials.

Moreover, with the ability to identify specific elements and to observe their magnetic domains, we can observe magnetic domains in a magnet for just dysprosium (Dy) or just neodymium (Nd). Using data from quantitative analyses of Dy magnetic domains, we learned that energy increases at the domain walls in response to grain boundary diffusion of Dy, leading to higher coercivity.

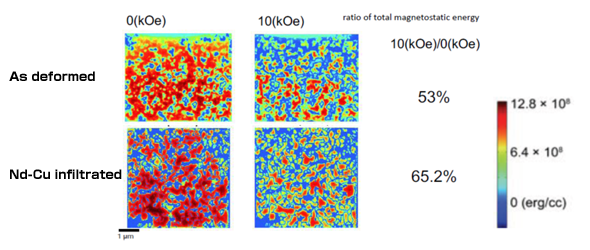

Direct visualization of magnetic energy is also possible using an X-ray microscope. Through this technique, we were able to observe a decrease in energy for magnetic dipolar interactions in hot-deformed magnets (Figure 1). This study showed that a magnetic field applied to a magnet that has not undergone an infiltration process by Nd-Cu produces an extremely large demagnetizing field from the neighboring grains, but this effect is reduced after performing Nd-Cu infiltration at the grain boundaries, revealing a high coercivity mechanism.

New characterization/analysis techniques using neutrons

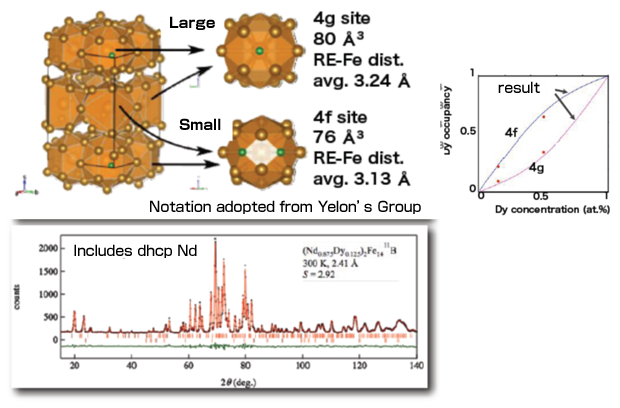

Structural analysis at the atomic level is made possible through neutron diffraction. One benefit of this technique is the ability to analyze crystal structures in neodymium magnets containing Dy. Rare-earth elements can occupy two sites in the crystal structure: 4f and 4g. Prior to this study, no experiments had confirmed which site Dy preferred. Therefore, we conducted neutron diffraction experiments to determine which of the two sites Dy enters, while varying the Dy concentration (Figure 2). We were able to construct a model that reproduced the experimental results using thermodynamic calculations based on the CALPHAD method and calculations of formation energy from first principles, indicating that site occupancy can be found through computation. These findings may contribute to the development of guidelines for designing materials with enhanced magnetic anisotropy.

Figure 1 Dipolar energy distribution of magnet according to infiltration of Nd-Cu eutectic alloy

Hot-deformed magnets with infiltration of Nd-Cu are known to have high coercivity. Magnetic dipolar energy changes when a magnetic field is applied due to the magnetization reversal process, but we were able to visually confirm that these changes were mitigated after Nd-Cu infiltration.

Figure 2 Structural analysis of neodymium magnets containing Dy

Crystal structure of (Nd1-xDyx)2Fe14B (top left). Site occupancies for the Dy element were found through concurrent analysis of neutron diffraction patterns (bottom left) and synchrotron X-ray powder diffraction. We formulated a method integrating the thermodynamic CALPHAD method and first-principles calculations that showed good compatibility with the experiment results (top right).

Kanta Ono

High Energy Accelerator Research Organization (KEK)

Research Collaborators

M. Yano, T. Shoji, A. Manabe, and A. Kato of Toyoto Motor Corporation; T. Ueno of Kansai Photon Science Institute; T. Abe of National Institute for Materials Science; S. Doi of the University of Tokyo; K. Saito and J. Kohlbrecher of Paul Scherrer Institut; Z. Fu and V. Pipich of Forschungszentrum Jülich; and U. Keiderling of Helmholtz-Zentrum Berlin

References

- K.Ono; Materia Japan, 56,199(2017)

- T.Ueno et al.; AIP Advances 7,056804(2016)

- K.Saito et al.; J. Alloys. Compounds 721,476(2017)

- T.Ueno et al.; Scientific Reports 6, 28167(2016)