Conversations with Young Researchers: Interview 4

Chen operating the JEOL 2000FX scanning transmission electron microscope

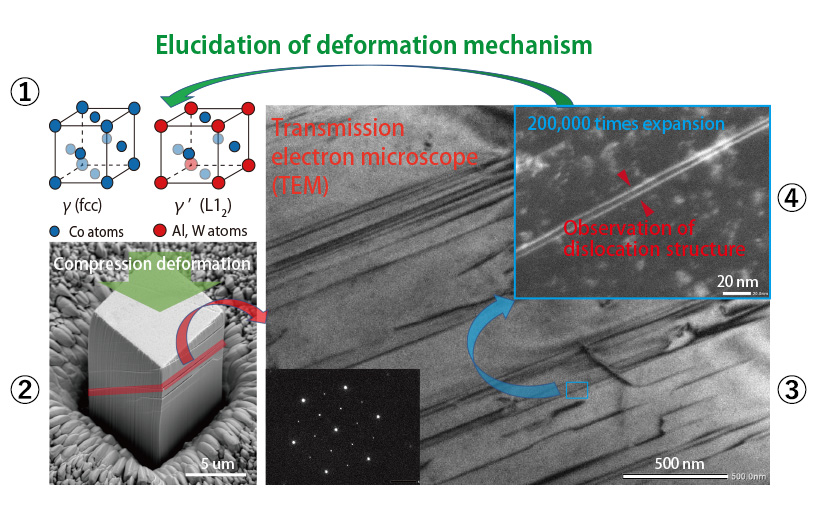

The area surrounded by yellow arrows in the upper right schematic diagram is the core of dislocation, and b indicates the direction of slip or dislocation.

The microstructure of a Co-based superalloy is shown in the lower right.

Why my research is fascinating!

Structural materials may seem like a dull subject, but they are fascinating because you can learn everything about them through experiments, from creating your own samples and analyzing them with instruments to finding logical explanations for the analytical results. Moreover, the study of structural materials will help you grow as an individual because the field has such a high ceiling, and you will not tire of it no matter how hard the work.

- “I decided to attend Kyoto University because I love the city of Kyoto”

- “I felt a surge of joy when I succeeded in capturing a clear image of the dislocation”

- “The hurdles of research and language were high”

- “Martial arts have given me support and instruction”

- “Simulation expectations for materials research that has relied on intuitive calculations”

“I decided to attend Kyoto University because I love the city of Kyoto”

“The winters in Kyoto are so mild.” While riding his bicycle along the Kamo River one day, Chen began thinking about his hometown of Beijing. In Beijing, the capital of China, temperatures can drop below -10℃ in the winter.

Seven years earlier while he was still a junior at Beihang University, Chen came to Kyoto as an exchange student to study at Ritsumeikan University. After graduating from his university in Beijing, Chen enrolled in the Graduate School of Engineering at Kyoto University. He chose Kyoto University because of his love for Kyoto. The lifestyle and culture were solidly grounded in history, and he liked the fact that the people of Kyoto did not walk so quickly like they do in Tokyo and Osaka. Also, the motto at Kyoto University is “freedom of academic culture.” He lived about 2 kilometers from Yoshida Campus and always commuted to school by bicycle.

Chen did not decide to study abroad until after coming to Kyoto, but he had studied Japanese on his own since high school. Perhaps he had simply always had the desire to study in Japan, but he maintains that he had no specific motive for coming.

Chen majored in Materials Science and Engineering at Beihang University. It was a very natural choice as he had been interested in engineering since a young age and had even made his own experimental equipment. For his senior year, Chen entered the laboratory of Professor Chaoli Ma where he learned a great deal about condensed matter, such as light materials. After continuing on to graduate school, Chen was assigned to Professor Haruyuki Inui’s laboratory at Kyoto University where he began studying the properties of crystalline materials, such as metals and alloys.

“I felt a surge of joy when I succeeded in capturing a clear image of the dislocation”

When an external force is applied to a metallic material causing deformation, the material does not return to its original shape after the force is removed. This type of deformation is called plastic deformation and occurs when atoms slide over each other along a specific crystallographic plane. Such movement does not occur all at once along the entire plane, but is effected by the movement of linear crystallographic defects called “dislocations.”

Dislocations look entirely ordinary, but their types of structure and movement vary the behavior of plastic deformation and are one factor that determines the mechanical properties of the material. Staff at Inui’s lab worked to identify correlations between dislocation substructures inside crystals and the mechanical properties of the material in order to develop a method of designing structural materials with higher performance. One of the targets of this research was intermetallic compounds. Intermetallic compounds are compounds having metallic atoms of differing properties with a mutually ordered arrangement and exhibit unique properties that differ from alloys whose atoms are randomly arranged. Many high-temperature structural materials, such as superalloys having excellent strength at elevated temperatures, rely heavily on these unique properties.

Chen’s first research task was to evaluate dislocations by measuring the mechanical properties of the material. “Now I realize I was working on a material for beginners,” he recalls, “but I had a difficulty observing the dislocations properly.” The material he was working on was one with high symmetry, such as a face-centered cubic (fcc; a structure having an atom located at each lattice point and the center of each face of the unit cell forming the crystal). Since there are fewer elements to study in materials with high symmetry, analysis is easier.

To observe dislocations, one creates an alloy by mixing together the constituent metals, controls the microstructure through heat treatment, and cuts off test pieces. The samples are then subjected to compression and tension while varying the ambient temperature among normal, low, and high temperatures to observe the plastic deformation. Dislocations inside the crystal move along a slip plane to the sample surface, and an accumulation of these dislocations forms steps in the surface. Therefore, one must first identify the slip plane by observing the surface with an optical microscope, for example. Microstructures of the dislocations are then magnified with a transmission electron microscope in order to analyze the process by which the dislocations were formed. At this time, the sample must be prepared thin enough (several tens of nanometers) for the electron beam to pass, and the sample tilt must be adjusted precisely so that the electron beam is diffracted only by a specific atomic plane in order to produce sharp contrast in the dislocation image. This requires comprehensive knowledge of crystallography and patience in the experimentation procedure, which is precisely why Chen was beside himself with joy when he successfully captured a clear image of the dislocation structure, and why he immediately ran to report this success to Professor Inui.

Chen also investigated high-temperature strengths of L12-ordered intermetallic compounds. While atoms at lattice points are not differentiated from atoms in the center of faces of fcc structures, such differentiation is made in L12 structures. For example, in a cobalt (Co)-based superalloy used as a high-temperature heat-resistant material, some aluminum (Al) and tungsten (W) are melted into the cobalt matrix, and these elements create the face-centered cubic structure (gamma phase: γ). On the other hand, a L12 structure (see the figure below) can be created with aluminum, tungsten, or the like arranged at the lattice points, and cobalt or the like at the centers of the faces (gamma prime γ’). Since the dislocations exhibit a unique structure and the material possesses excellent strength at elevated temperatures when the atoms have an ordered arrangement, intermetallic compounds having an L12 structure function as a “strengthening phase” for strengthening the superalloy.

Observing a dislocation structure

① Prepare single-crystal test pieces of γ or γ’ phase

② Deform the test pieces by applying force

③ Capture the dislocation slip plane

④ Enlarge the dislocation structure to analyze the mechanism of deformation

“The hurdles of research and language were high”

During his master’s program, Chen’s research was focused solely on de facto properties of the strengthening phase. In this research, he elucidated the process of plastic deformation from the perspective of the dislocation structure and, using this knowledge, predicted the effect of additive elements on strength, and particularly strength under elevated temperatures. Research during his doctoral program was expanded to include designing γ/γ’ two-phase superalloys, examining their mechanical properties at high temperatures, and assessing whether they could have practical applications. He also worked on clarifying guidelines for improving the service temperature of Co-based superalloys having L12-Co3 (Al, W) as the strengthening phase by systematically investigating how their high-temperature strength is affected by additive elements (Ni or Ti, for example). Chen compiled this research into his dissertation and received his PhD in March 2019.

Chen recalls those five years that culminated in his PhD. “It seemed to take forever. Personally, I feel that I worked very hard, but the hurdles of research were high, and I think language was also a barrier.” Professor Inui was strict in his instruction, not showing Chen any favoritism for being a foreign student. Once Chen got into a heated argument with Professor Inui when he had difficulty expressing a different point of view. “I was disrespectful, but he listened and took me seriously. Despite such incidents, I did not give up, and I was able to persevere until I completed my dissertation.”

Professor Inui recalls how Chen was as a student. “As a research student, a master’s student, a doctoral student, and now an assistant professor, Chen has been involved in research on structural materials throughout. While I think he faced some difficulties initially due in part to the language barrier, he is growing. He has recently acquired the skills necessary for handling TEMs and conducts research from plans he developed himself. He is currently leading a study for further improving heat-resistance in Co-based and Fe-based superalloys from the perspective of element strategy. I expect to see Chen make great strides hereafter.”

“Martial arts have given me support and instruction”

While Professor Inui’s support has been steadfast in Chen’s research life, martial arts have also been a major support. A fan of combative sports, Chen has regularly trained in Taekwondo since his third year of middle school. After coming to Kyoto, he became an instructor at a local dojo and even served as a referee for the Japan Taekwondo Association. In September 2014 he saw a demonstration of Chinese martial arts (Kungfu) held in Kyoto. Fascinated, he began studying Kungfu and also received instruction in spears, tai chi, and swords. While learning such extensive techniques in martial arts, Chen began to contemplate aspects universal to martial arts as a whole and came to the following realization. “I think research and martial arts have many similar attributes. When faced with any phenomenon, one has a compelling desire to ask why the phenomenon occurred and to consider the origins of the phenomenon. From this understanding, one can decide what to do next.”

This shift in thinking had a great impact on the way Chen conducted research. In addition to Taekwondo instruction, Chen began to consider mentoring and teaching the younger researchers in the lab. There are currently four younger students from China studying at Inui’s laboratory. Having experienced his own difficulties taking part in high-level discussions with Professor Inui, Chen took it upon himself to become involved with the younger students to offer his support. In order to create an environment in which the students could talk candidly about their research, Chen began inviting them to join him for coffee or lunch, endeavoring to make their discussions fun. This also gave Chen an opportunity to broaden his own perspective since the students were all involved in different research topics.

One of the exchange students, Li, was grateful for Chen’s thoughtfulness. “He was very approachable and always willing to give us advice about an experiment or our studies. With his help, my research is going well and I am enjoying my life here.”

“Simulation expectations for materials research that has relied on intuitive calculations”

In 2005, the cobalt-based superalloys that Chen has been researching were proposed as a candidate ultrahigh-temperature material that could surpass the performance of nickel-based superalloys, which are currently in widespread use. Nickel-based superalloys have been used over the last few decades in aircraft jet engines and power-generation turbines, and while their performance has improved during this time, they are said to be approaching their limits. However, the requirement of attaining a practical cobalt-based superalloy, and specifically achieving both strength and oxidation resistance, has proven difficult, and the prospects for such superalloys have dimmed of late.

On the other hand, research on cobalt-based superalloys has led to the establishment of methods of observing dislocations and techniques for analyzing the material’s properties based on these dislocations. The future direction of research is to learn how these techniques can be applied to elucidate the properties of unknown materials and to improve the strength of materials. As one example, studies are being conducted on Fe-based superalloys utilizing L12-structured Fe3Ge as the strengthening phase. Chen has also just begun researching new materials like high-entropy alloys. High-entropy alloys are stable alloys literally formed by mixing together equal amounts of several dissimilar metal atoms, whereby atoms of different elements become randomly distributed in the crystal lattice (known as high configurational entropy). In recent years, it has been demonstrated that these alloys exhibit many superior properties not found in their constituent elements, such as excellent ductility at low temperatures and strength that scarcely degrades at high temperatures. However, the novel concept of these materials cannot be explained by conventional theories.

How does one search for candidate materials possessing such new physical properties? “Both cobalt-based superalloys and high-entropy alloys were developed while referencing simulation results. Simulations are useful, but some aspects cannot be understood without conducting experiments. A considerable number of materials researchers rely on their intuition, but at this stage I think it is necessary to test each candidate material one at a time. However, since it is difficult to convey intuition to other people, these methods are still usually communicated through simulations and mathematical formulae.

When asked about his future goals, Chen responded, “The mechanisms by which dislocations occur are not yet fully understood. Therefore, I would like to continue conducting analytical studies on dislocations. Eventually, I hope to be able to analyze plastic deformation behavior from the perspective of dislocations for any crystalline structure, and ideally this will lead to the development of practical materials.

Needless to say, Chen will also continue his pursuit of martial arts.

Chen helping a graduate student conduct tension tests using a universal tester

Profile

Chen Zhenghao

Assistant Professor at the Elements Strategy Initiative for Structural Materials (ESISM), Center for the Promotion of Interdisciplinary Education and Research (C-PIER), Kyoto University

July 2013

Graduated from the School of Materials Science and Engineering at Beihang University

April 2014

Entered the Department of Materials Science and Engineering, Graduated School of Engineering at Kyoto University

March 2019

Received a PhD from Kyoto University

April 2019

Engaged as a researcher at the Elements Strategy Initiative for Structural Materials (ESISM), Center for the Promotion of Interdisciplinary Education and Research (C-PIER)

October 2019

Appointed to assistant professor at ESISM, C-PIER

Photographs by Takuya Oshima; interview conducted by Sakiko Fukushima of Sci-Tech Communications