Fuel-efficient Tire Development by Complimentary use of Quantum Beam and a Supercomputer

- Observation

- Computation

-

-

- Understanding the internal structure and its dynamics of rubber is important for producing desired properties and functions in tread rubber

- Conducting research using a combination of X-rays, soft X-rays, muons, and neutrons

- Utilizing computer simulations in combination with experiments

Requirements for improving tire performance and developing next-generation tread technologies

To improve tire performance, it is necessary to increase grip performance, fuel efficiency, and wear resistance, but these three performance traits are inherently conflicting. Improving all three key traits and developing next-generation materials technologies will require capturing and controlling never-before-seen internal structures of rubber materials.

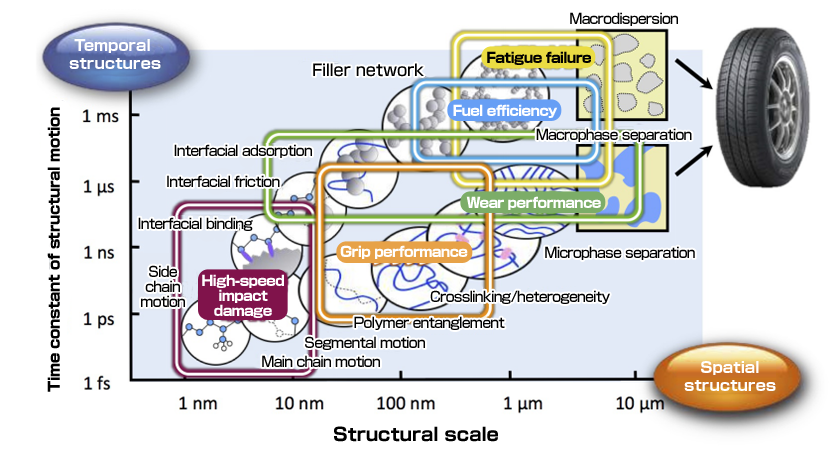

Tire rubber has an extremely complex composition of roughly ten or more material components. Functions of the rubber material are manifested through complex interactions among hierarchical structures ranging from the nanoscale to the macroscale. Rubber material also exhibits functions over a broad temporal scale. Therefore, it is essential to learn the response characteristics and dynamics produced by internal structures of rubber materials.

Utilizing quantum beams to study hierarchical structures and molecular dynamics of rubber

Isolating the dynamics of grip, fuel consumption, and wear in rubber materials has simply not been possible through conventional structural analysis alone. However, we thought it might be possible to separate grip and fuel consumption based on the time scale, for example (Figure 1). The tools we used for observation were synchrotron radiation at SPring-8 and neutron beams at J-PARC. With a combination of X-rays, soft X-rays, muons, and neutrons, we conducted studies on the hierarchical structures and molecular behavior of rubber materials.

The results of this study show that silica particles in the rubber form a network comprising a primary aggregate structure and a secondary aggregate structure. We also learned that the exceedingly high orientation of the polymer increases strength in the strain range throughout the entirety of which stress is present, changes in the hierarchical structures of silica trigger various changes in the polymer that enhance the rubber’s strength, hysteresis loss is closely related to structural changes in the silica, and the presence of higher-order aggregates affects fuel efficiency.

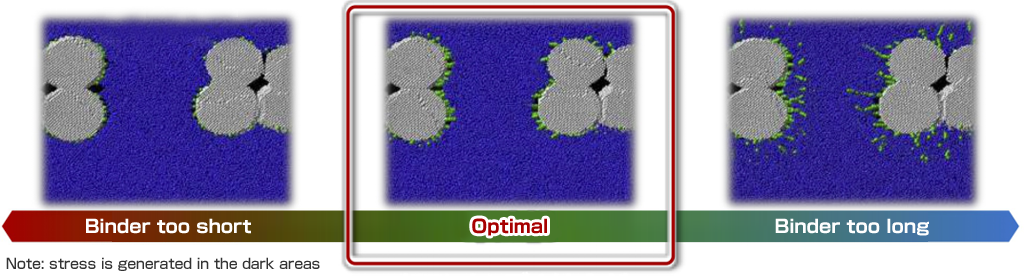

Suspecting that the silica interface polymer plays a large role in the material properties, we also studied the molecular dynamics of adsorbed polymer on the silica interface using quasi-elastic neutron scattering at J-PARC and investigated the polymer structures based on neutron reflectivity. The results of this study indicate that the dynamics of adsorbed polymer at the silica interface and interaction between the silica and polymer are very closely related to fracture in rubber.

By conducting computer simulations based on these experimental results, we succeeded in finding an optimal molecular length for the coupling agent capable of suppressing fracture (Figure 2). The results of these simulations not only raised grip performance and fuel efficiency to their highest levels, but wear resistance also improved by 50% over conventional levels when even a 10% increase would have been welcome.

Seeking a better understanding of the internal structures and its dynamics of tread rubber

The performance traits of grip, fuel efficiency, and wear in tires all change over time. A better understanding of the chemical states of organic matter will be essential for minimizing this decline in performance and for developing next-generation materials technologies. For these studies, we intend to use the high brilliance of soft X-rays.

Our understanding of the internal structures and its dynamics in tread rubber will likely be improved by utilizing coherent X-ray diffraction imaging and other tools to study specific locations in the internal structures in greater detail.

Figure 1 The tire performance (predicted) for temporal-spatial hierarchical structures in rubber materials

Figure 2 Simulating the effects of binders on rubber failure

Hiroyuki Kishimoto

Research & Development HQ

Sumitomo Rubber Industries, Ltd.